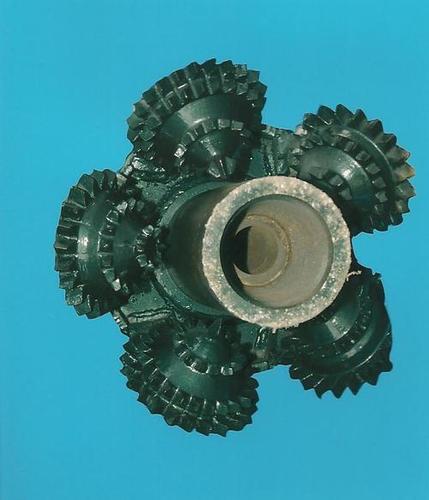

Drill Rods

Product Details:

- Condition New

- Noise Level No Machine Noise

- Diameter 8mm to 39mm

- Machine Type Drilling Accessory

- Features High Wear Resistance, Precision Ground, Corrosion Resistant Finish

- Dimension (L*W*H) Diameter: 8mm to 39mm, Length: 300mm to 1500mm

- Product Type Drill Rods

- Click to View more

Drill Rods Price And Quantity

- 30 Piece

- 300.00 - 500.00 USD ($)/Piece

Drill Rods Product Specifications

- No Machine Noise

- New

- High Carbon Steel

- Normal

- 8mm to 39mm

- 2 to 12

- Drilling Accessory

- Mining, Geological Exploration, Construction Drilling, Water Well Drilling

- Drill Rods

- Black

- Manual

- Diameter: 8mm to 39mm, Length: 300mm to 1500mm

- Manual

- High Wear Resistance, Precision Ground, Corrosion Resistant Finish

- No

- Depends on Diameter and Drill Depth

Drill Rods Trade Information

- Chennai/Mumbai

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID)

- 24 Piece Per Month

- 4 Week

- Contact us for information regarding our sample policy

- standard Export & Packaging

- Australia, Middle East, Western Europe, South America, Eastern Europe, North America, Central America, Asia, Africa

- All India

- ISO 9001:2008

Product Description

Making our identity shine in this business segment with first-rate Drill Rods (Friction Welded). Our business entity has brought ahead the mentioned rods whose performance is worth trusting. The given rods are developed keeping in view arising modern expectations of users. The quality is designed to function for long without giving rise to any type of problem. The price of provided rods is right and this serves as great factor of our powerful relationships with customers. Our business unit serves mentioned drill rods that can be used in extremely tough environments with ease. We meet orders of Drill Rods (Friction Welded) at a promised time.

We are the leading manufacturers of Drill Rods (Friction Welded).

- Sizes : 3,3 , 4 & 5

- Length : 5, 10, 13, 15, 20 & 30

Superior Durability and Precision

Designed for heavy-duty drilling environments, our drill rods boast high wear resistance and a corrosion-resistant finish that withstands challenging conditions. Each rod is manufactured to stringent standards, with precision-machined pin and box connections for secure assembly, and offers minimal deviation thanks to strict straightness tolerances. This ensures consistent performance and extended tool life on every project.

Versatile Applications Across Industries

Engineered for versatility, our drill rods serve a range of industries including mining, geological surveys, water well creation, and construction. The selection of thread types and diameters enables compatibility with major drilling machines and accessories, making them an ideal choice for operators seeking reliability and adaptability in demanding fieldwork.

FAQs of Drill Rods:

Q: How are the drill rods manufactured to ensure high wear resistance and precision?

A: Our drill rods are fabricated from high carbon steel that undergoes heat treatment and black oxide finishing. Each rod is precision ground and machined to maintain strict straightness tolerance (0.02mm per 1000mm), providing enhanced wear resistance and reliable performance during drilling operations.Q: What types of threads are available for these drill rods and why does thread selection matter?

A: We offer NW, AW, BW, HW, PW, and SW thread types, ensuring compatibility with various drilling systems and tools. Choosing the correct thread is essential to ensure a secure connection, efficient torque transmission, and safe operation in diverse drilling environments.Q: Where can these drill rods be used and what are their typical applications?

A: Our drill rods are suitable for mining, geological exploration, construction drilling, and water well drilling. Their robust design and corrosion-resistant finish make them ideal for use in both surface and underground operations across multiple sectors.Q: What is the process for packaging and shipping the drill rods to ensure safety and integrity?

A: The drill rods are packed securely in wooden cases or bundles, protecting them against damage during transport. This packaging method maintains the rods straightness and surface quality, ensuring they arrive in optimal condition for immediate use.Q: When is it recommended to replace drill rods during ongoing projects?

A: Drill rods should be inspected after each use for signs of wear, deformation, or loss of straightness. Replacement is recommended when rods exhibit significant surface wear, reduced connection integrity, or fail to maintain required straightness tolerance for safe and effective drilling.Q: What are the primary benefits of using these high carbon steel drill rods in manual drilling operations?

A: These drill rods offer unparalleled durability, corrosion resistance, and precise alignment, reducing operational downtime and maintenance costs. Their manual assembly and robust design ensure ease of handling and consistent performance even in demanding field conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Drilling Rig Accessories' category

|

PRIME HITECH ENGINEERING LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |